This Programmer is powered by the RS-232 and it works with RS-232 levels at only < ±8.6V. It programs PIC12C5XX, 12C67X, 24CXX, 16C55X, 16C61, 16C62X, 16C71, 16C71X, 16C8X, 16F8X and ISO-CARD's with ASF. Other serial programmable chips by adapter.

How to connect the wires.  | Schematic |

The high Vpp is obtained by using negative voltage to drive the chip. The voltage is stabilized with zener diodes. They do not need voltage drop as if a voltage regulator, or has much offset current. This makes it possible to use extra low input voltage. Transistor driver guarantee output level > ±3V.

Features: Utilities now work on Dos, Windows 3.1, Windows 95, Windows 98 and are expected to work on all other operating systems. All software does modemcheck to ensure that modems flash are not programmed by programmer, e.g. if you forgot to swap cable between programmer and modem. It is now possible to program more chips at same time using more of the communication port's while multitasking under Windows. The software automatic optimize delay for cable length and works with modem cables up to 100m. It use the RS232 controler chip only, and does not invoke use of other timers. Also short programming pulses are now hardware controled. Laptops only tested with PIC16C8x and 24Cxx.

The Programmer supports ICSP, In-Circuit Serial Programming.

D5 and D7 may be replaced by a BC557B. Emitter to MCLR and Collector to Vss.

EEPROM adapter for this programmer. (Supports Automatic Switch Function and LC types.)

Schematic for the programmer.

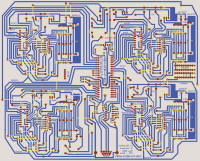

PCB for this programmer.

Detailed Funtional Describtion.

Download PIP02 beta driver, JDM84V33.ZIP (5K).

Works with windows too.

Download PIC16C84 utilities, PGM84V34.ZIP (38K).

Download PIC16C84 utilities, PGM84V35.ZIP (38K). (Beta version)

New PIC12C508 algorithme, P50XV21.ZIP (32K).

New PIC12C508 algorithme, P50XV22.ZIP (32K).

The utilities is inclusive source. If problems, then use slow version.

Updated 16 dec. 1999.

Most easy PIC-Programmer ever.

Most easy PIC-Programmer ever, w. 220V lamp edition.

Ultra lowcost for PIC16C84 only.

Simple programmer for PIC16C84 and 24Cxx only.

Applications:

How to use the programmer with In Circuit Serial Programming.

Connection to ISO-CARD with Automatic EEPROM Switch.

Problems?

You may need a diode in RS232 ground, but 24Cxx programming does not work when connecting a diode. Mail if diode is needed. I am not sure if it is computers that need the diode.

Schematic.

Always use last version of software. PGM84V29 has been improved to work better with laptops, and P50X has been updated to use a better algorithme. PGM84V32 and P50XV19 work better - and problems has been solved. P50XV20 is much slower, old versions was too fast.

New in PGM84V34: Small bug, according to Sebastian Edman and Malte Kiesel is corrected.

Also changed to be able to be compiled with free pascal. (Still able to be compiled with Borland Pascal). Last update: 16. dec 1999.

In case you develope your own routines, and do support my programmers, you do need to check voltage during read, and also programming voltages, since it depends on delays too. Test with more cable lengths are needed and must not result in programming / reading problems. Very slow interrupts, as e.g. exists in multitasking environments, must not make the voltages drop. An easy multitask test is to program more chips at same time using multiple ports.

Notice: If delays are too short, will PIC12C50X hang and need to be unpluged (Power removed) - and inserted again. Then it works. Use slower version (new versions or PROG50XS.BAT). If 3FFF at read, also use the slower versions. (READ50XS.BAT). Else does it hang, and reads blank.

Free routines: You may use my routines for the PIC-programmer in your own software, but only if your software is free- or if it is shareware. If any changes in my programming routines, it should be described with the documentation of your software package.